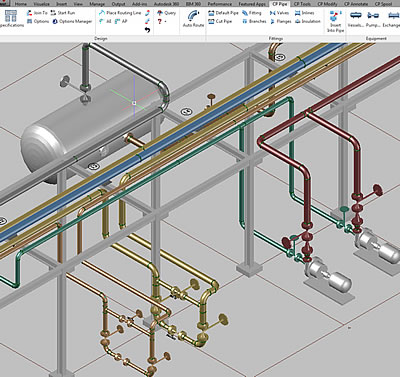

All made easy by the program’s intelligent background checking. Automationĭraw vessels by simply selecting two corners, sequentially place piping components with AutoRoute, annotate valves and generate BOMs. Piping application will allow you to proceed with the override after alerting you of the pending deviation from standard practices. Spec override optionsĮasily override the operational spec if necessary. Save and control important settings for each project (or each client), which includes drawing units, location of drawing files storage, allowed pipe specs, border drawings, BOMs and many other important settings. Spec-drivenĪlways use compatible pipe specs with background compliance-checking.

Piping components come in flanged, threaded, socket weld and butt-weld configurations. Vast selection of pipe fittings, flanges, valves and supports to make your job easier. The included modules are to facilitate the creation of pipe specs, design BOM templates and to organize your projects to suit customer standards. Complete set of tools for all your drafting needsĮvery software product come with the tools you need to manage your design office. Other features include easy-to-use pre-built components, like flanges, nozzles, elbows, gaskets, valves and supports to make drafting easier. Features include the ability to Auto-Route piping components as well as auto-generate Bill of Materials (BOMs). Wet paint overspray has to be disposed of as chemical waste.Each piping application comes with essential automation and data management tools. The powder, not attracted to the substrate, is contained and reused.

This eliminates sharp edges that need to be ground into shape. This adhesion creates a smooth and even layer that covers the edges of the metal object. The environment also benefits from the electrostatic adhesion of the metal to the powder particles.

The harmful emission of V.O.C., as used in wet paint, does not occur. The powder is applied without any additives. Whereas wet paint is all washed up!Īnother advantage of using powder coatings is the subtraction of solvents. In addition, powder coating is more friendly to the environment than wet paint, for the same cost, yet powder coating also has the advantage of superior mechanical and anti-corrosive properties. Technically, powder coating competes with wet paint head to head. In the long run, powder coating will replace its counterpart, wet paint, in more and more areas. Decay and early replacement of parts are prevented or at best minimized. Our coating system protects the metals which are exposed to the project conditions, which in turn enjoy a longer lifetime and require far less maintenance. There is a positive long term effect of powder coating the product for corrosion protection. Despite all the care that is taken to protect the environment, there are still benefits to be gained.

0 kommentar(er)

0 kommentar(er)